AMP ONE Cleveland Case Study: Revolutionizing Waste Sortation with Fully Automated AI

How AMP ONE Delivers Fully Automated, High-Purity Waste Sortation Without Human Hands

Challenges: Labor Demands and Manual Limitations Slow Progress

Conventional material recovery facilities depend on labor-intensive processes. This model is costly, difficult to scale, and increasingly ineffective as waste streams become more complex. In Cleveland, the objective extended beyond reducing labor; it was about extracting greater value from waste while minimizing human involvement.

AMP set out to demonstrate that a fully autonomous system could improve both recovery rates and operational efficiency. The result was AMP ONE.

Solution: AMP ONE AI-Driven Sortation with Zero Manual Sorting

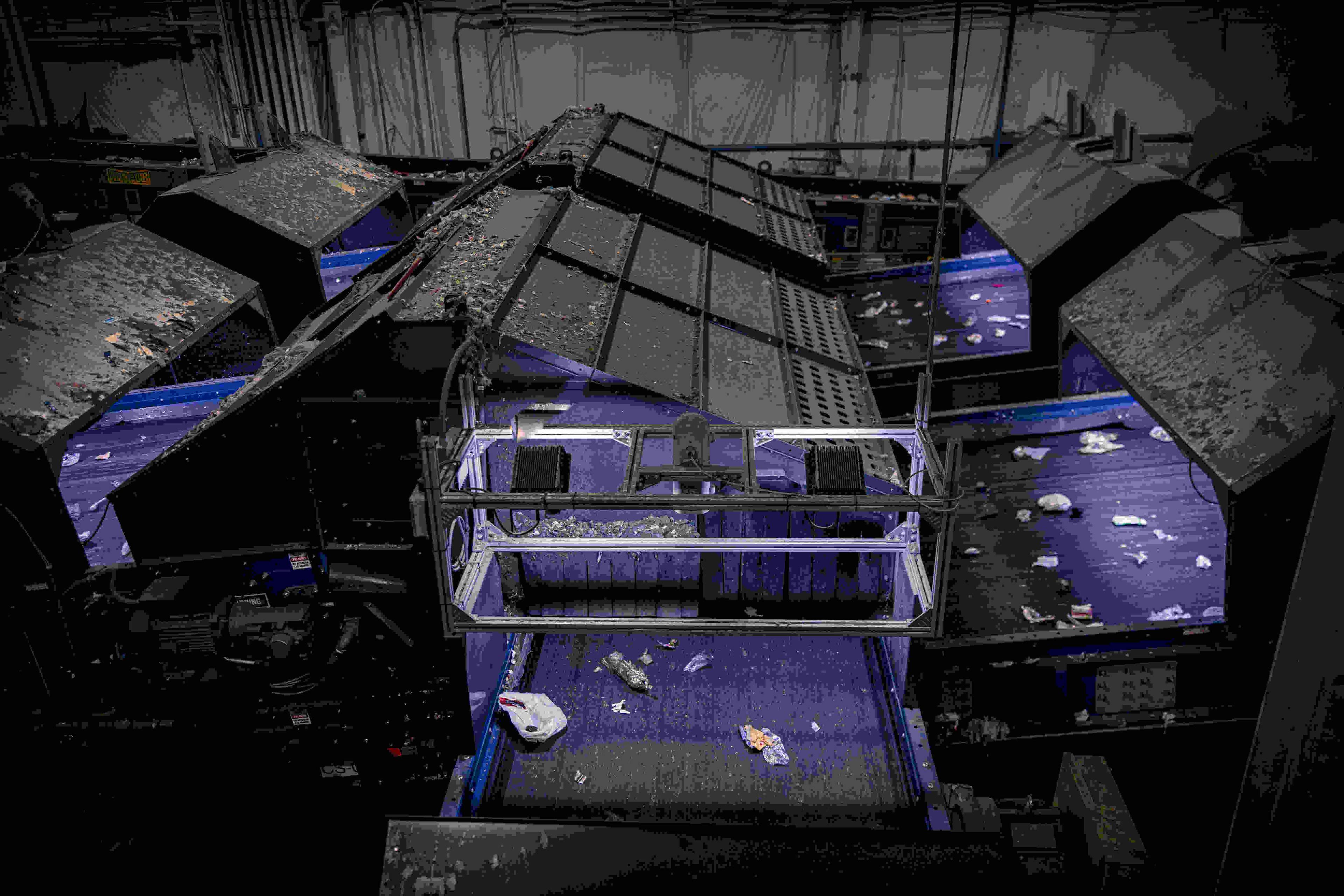

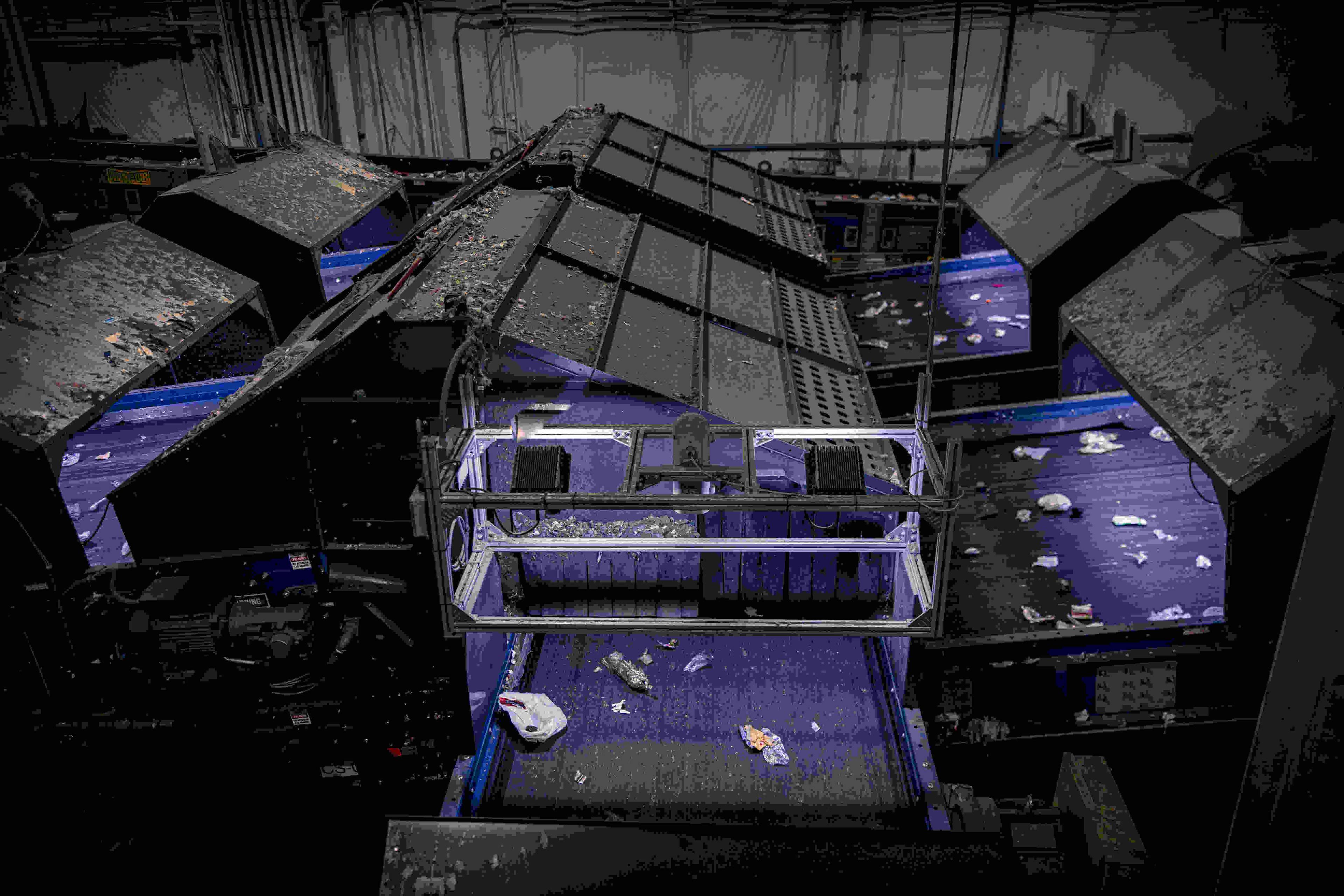

At AMP ONE Cleveland, up to 60,000 tons per year are sorted with no manual intervention. Visitors often ask, “Where are all the people?”, and the answer lies in AMP’s advanced AI and robotics. This facility redefines waste sortation by using real-time material recognition, fully automated machinery, and intelligent decision-making from start to finish.

AMP’s system identifies hundreds of categories and combinations of paper, plastics, and metals, assigning every bale a barcode tied to its exact composition and purity. The result is a hands-off, high-precision process that maximizes value and minimizes waste.

System Highlights

Technology Built for Accuracy, Flexibility, and Scale

AMP VAC: Pulls plastic film early in the process

- Sort by shape, polymer, material type, and even brand

- Double-Cut Sortation: Each jet processes two material streams at once

- Recirculation Line: Allows second or third passes to recover more value

- Automated Residue Monitoring: Purges based on material load thresholds

- Barcode Tracking: Connects each bale to real-time data on purity and content

- All of this is guided by AMP’s proprietary AI, which adjusts sortation strategies on the fly based on material flow and recovery priorities.

Results: Labor-Free Processing with Higher Material Quality

Fully Automated Operations

AMP ONE removes the need for manual sorting entirely. A small team handles only performance checks and maintenance, freeing operators from recruiting or managing a sortation crew.

Improved Purity and Material Traceability

AI-powered vision enables precise separation and grading of mixed materials. Every bale produced is traceable, market-ready, and meets high purity standards.

Real-Time System Optimization

Sortation strategies can be adjusted instantly to respond to changing material streams or market demands. This gives Cleveland's AMP ONE a competitive edge in maximizing recovered value.

Less Waste, More Recovery

The system recovers more usable material and sends less to the landfill by design. Recirculation paths and smart purging keep valuable resources in play longer.

Looking Ahead

A Scalable Model for the Future of Waste Processing

AMP ONE Cleveland is a facility and a proof of concept. With no manual sorting, complete automation, and unmatched transparency, it represents the future of material recovery.

As Kevin Papich, Director of Facility Operations at AMP, explains: “All you have to do is drop off and pick up. AMP does the rest.”

Cleveland’s AMP ONE offers a smarter, scalable path forward for operators looking to reduce costs, improve quality, and future-proof their recovery strategy. AI-driven sortation is the new standard.

See How AMP Smart Sortation™ Can Transform Your Operations