Our Waste Sorting Technologies

Waste Processing, Redefined.

AMP has reimagined the MRF from the ground-up, based around data and low-cost precision sortation. We've created a hands-off system that operates using advanced manufacturing techniques and leverages data-driven automation.

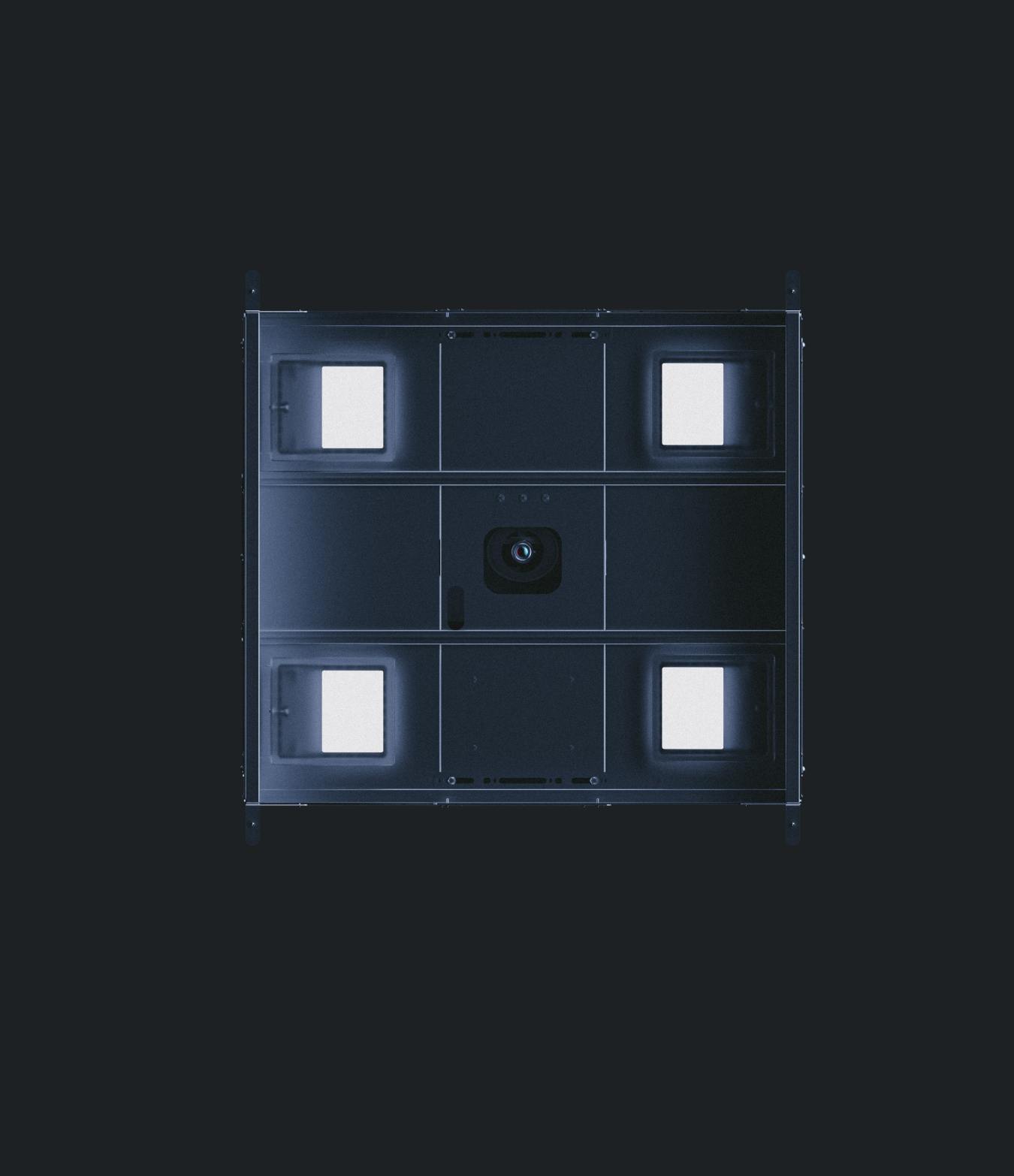

Our Powerful Neural Network

AMP’s AI can classify any visible material property: food-grade, brand, color, form, wrappers, closures, and more. It identifies material despite contamination levels that would confound traditional sorting systems, and it pairs with NIR for ultra-pure resin applications. Each AMP ONE sensor updates remotely within 4-6 weeks, improving through data from billions of items.

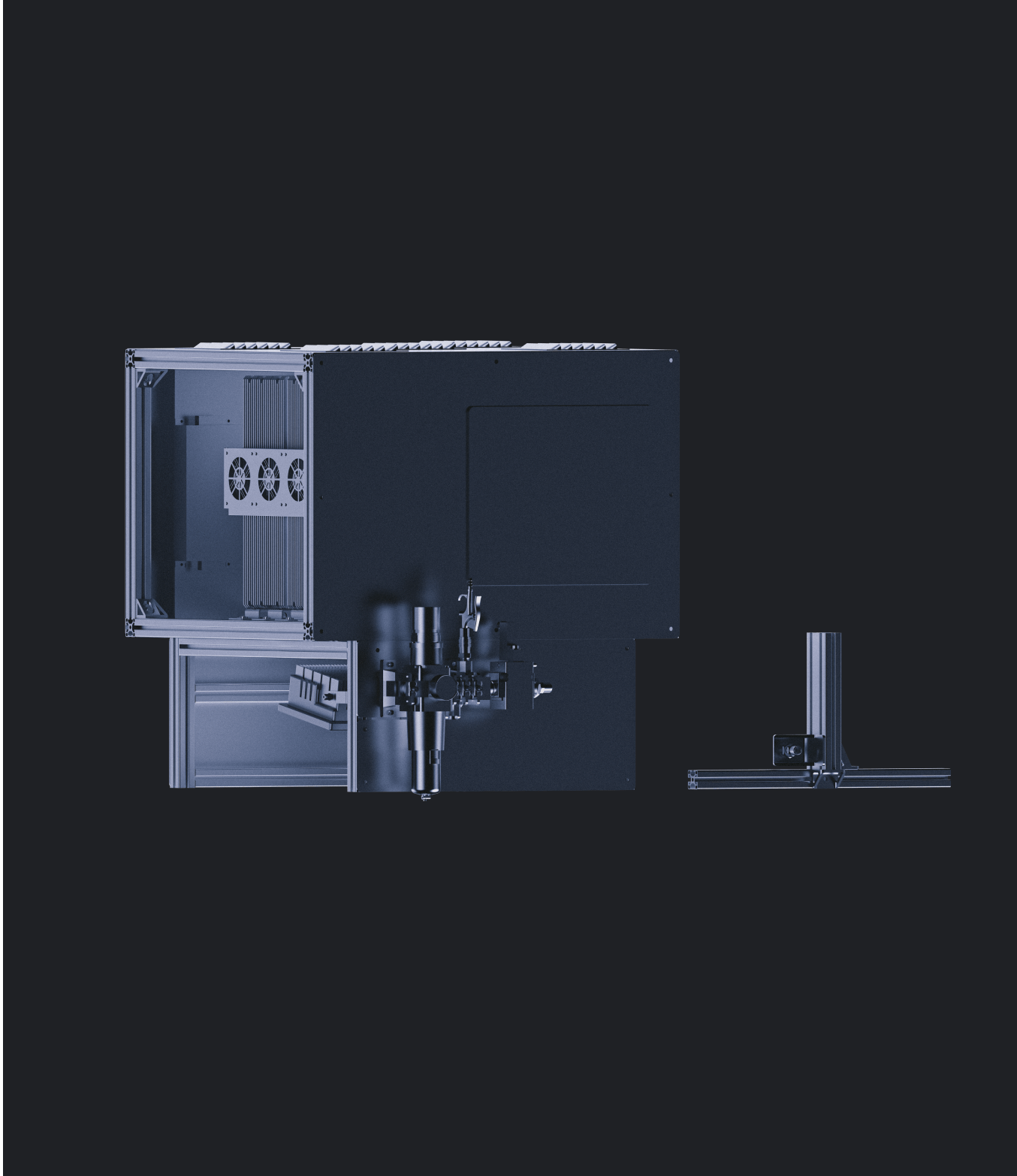

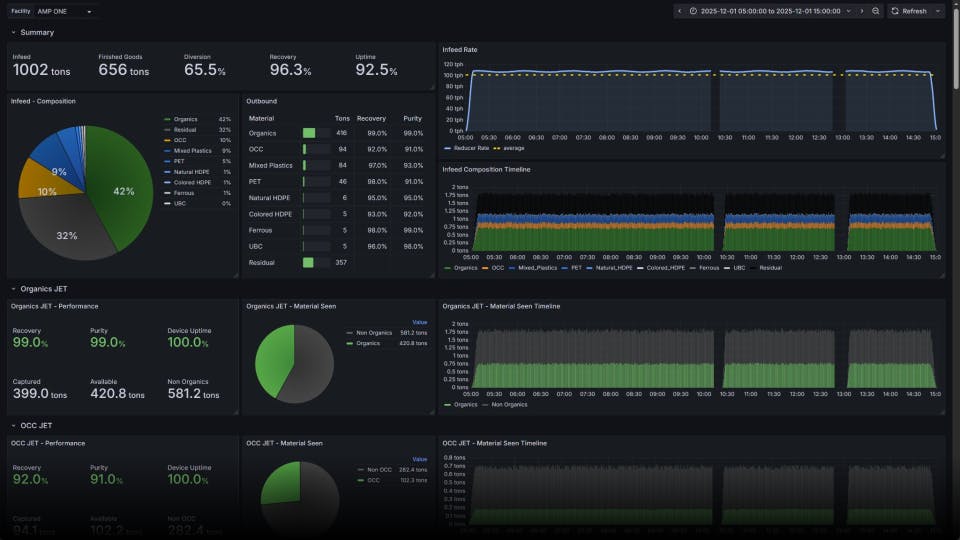

Data Rich Environment with Custom Control

AMP systems harness comprehensive data to stay ahead of issues. We track equipment metrics like cycles and torque to predict maintenance needs and pair this with AI-driven camera data to monitor material flow across the facility. This enables automated baling and accurate, real-time reporting on mass flow and recovery.

AMP ONE builds on this intelligence with a smart control layer that delivers smooth, hands-off operation. Features like jam detection and self-clearance, real-time composition and bale quality tracking, and automated baler scheduling ensure consistent, high-quality output and maximum efficiency.

Unique system design

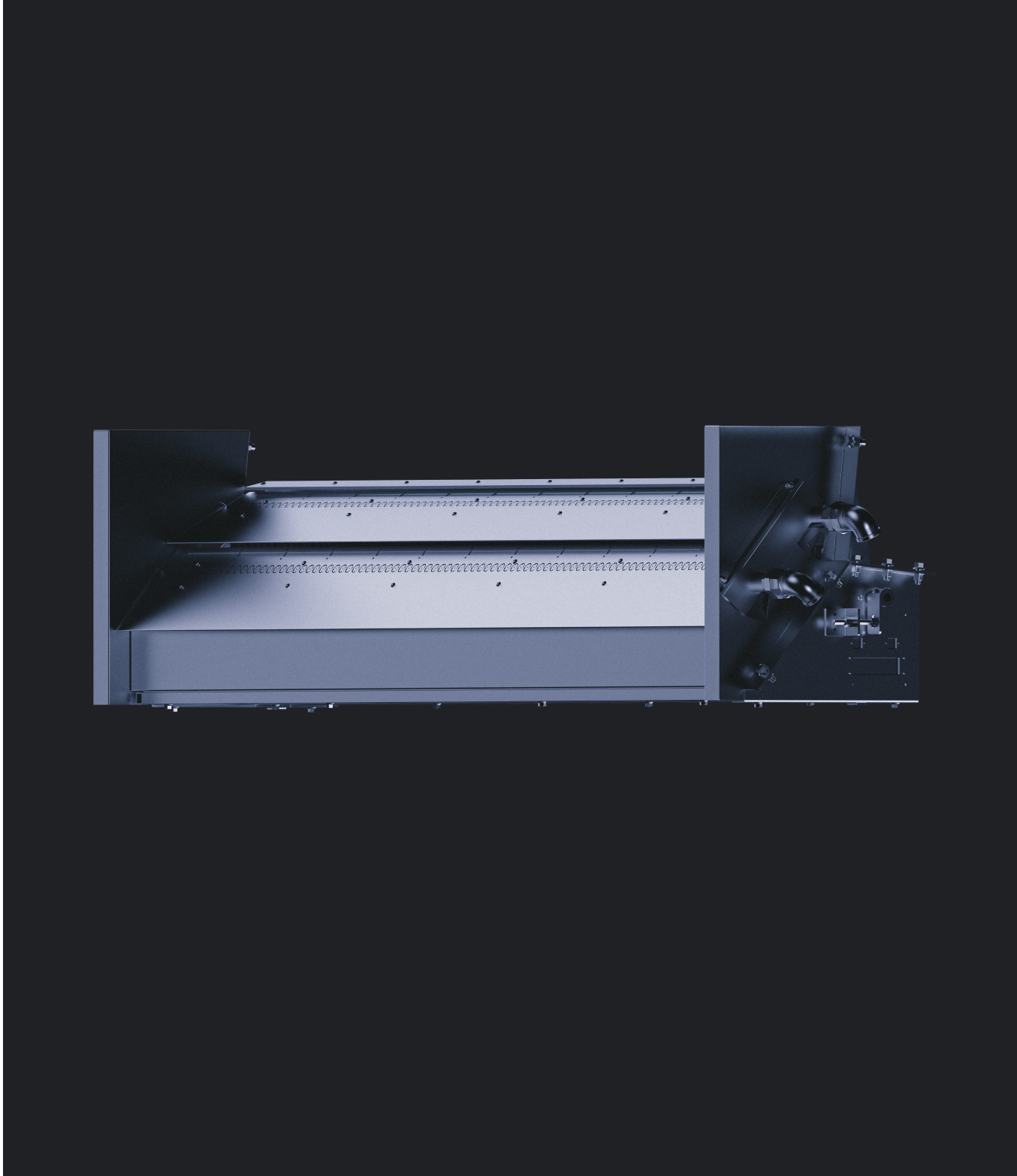

Touchless, Precise Sorting

AMP ONE redefines the MRF, relying almost entirely on air-based sorting with minimal human contact, all powered by the low-cost, compact, flexible AMP Jet.

Always Improving

AMP ONE is the only facility that gets better over time. It can self-calibrate, intelligently avoid overlapping items, and even reconfigure at the click of a button, providing unmatched flexibility, built-in redundancy, and uptime above 90%.

Built for the Future

AMP ONE is EPR-ready and future-proof out of the box. It comes with built-in composition analysis, characterizing all material run through the system and any sort point can be reconfigured to handle new commodities.

The Only Choice for MSW

Most MSW facilities face high costs and low performance. AMP leverages its technology to create compact, cost-efficient systems that overcome detection and sorting challenges and deliver higher diversion with more than 90% uptime. We finance, develop, build, and operate the solution while guaranteeing performance.

Custom Organics Solutions

We sort your organics to spec with our industry-first AI+NIR organics jet, capable of precision sorting down to 12 millimeters for cleaner material. Paired with industry-leading technologies and our network of partners, we design and deliver organics solutions tailored to your region.

AMP Portsmouth

AMP Technologies

Put the power of AMP Smart Sortation™ to work for you.