The Most Reliable Robotic Sortation

The AMP Delta™ robotic sortation system processes material up to four times faster than manual sorting, and with greater accuracy and consistency.

How do AMP Technologies Fit In My MRF?

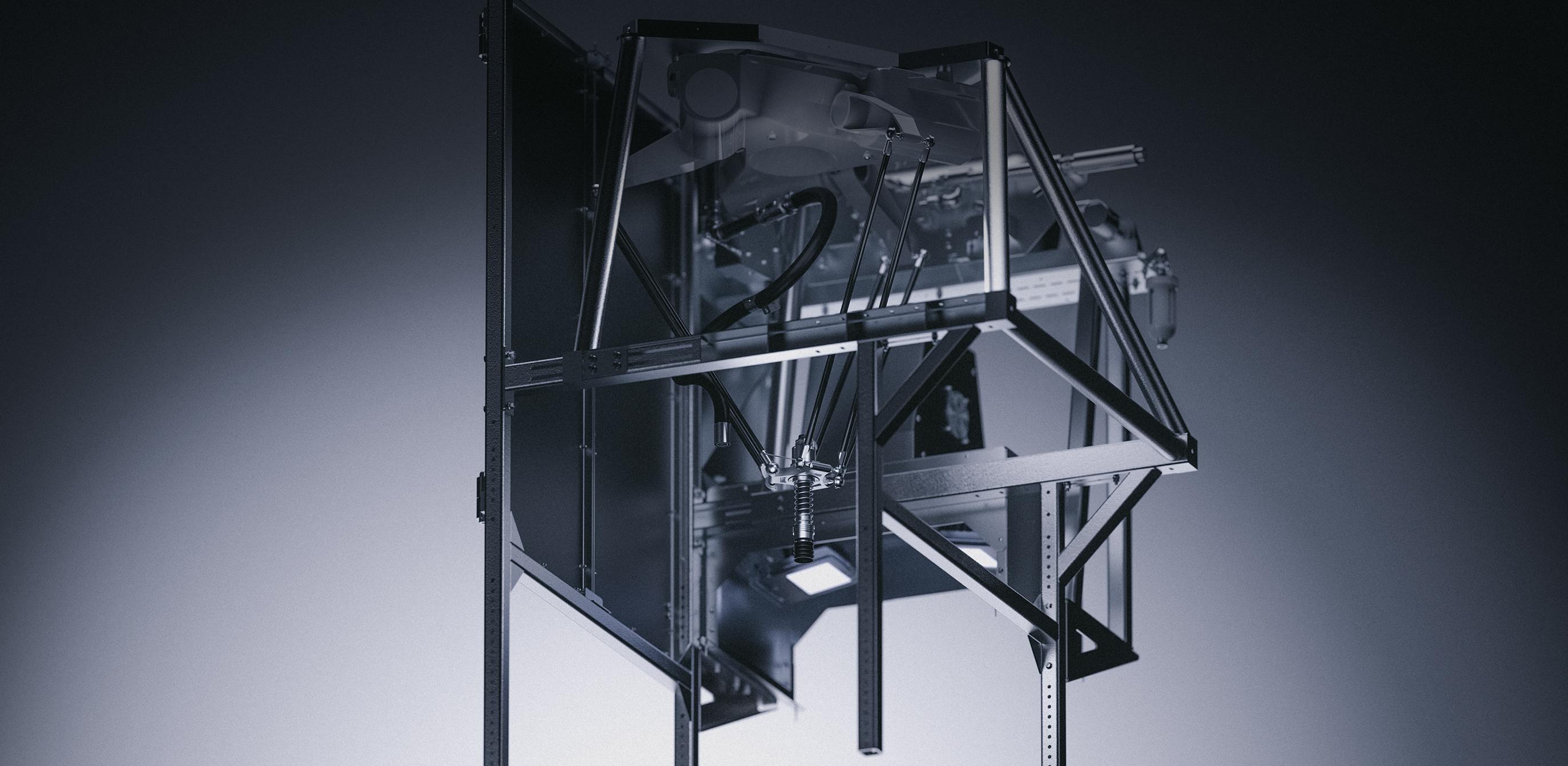

Robotic Sorting Systems

Material approaching AMP Delta is scanned by an AMP Vision system, which recognizes specific materials, even at high speeds within complex waste streams.

AMP Vision sends imagery to AMP AI—our proprietary artificial intelligence system—which identifies individual items by material type, form factor, color, polymer, and even brand.

AMP AI then directs the Delta robot (or robots) to target and recover material based on your real-time specifications and commodity value.

AMP Delta self-monitors for performance, and alerts your team if service is required—often as simple as clearing a tube or replacing a suction cup.

Which Delta Model is Right for My MRF?

AMP Delta replaces human sorters with a high-speed, AI-powered solution for faster and more precise recovery of material.

Caglia Environmental

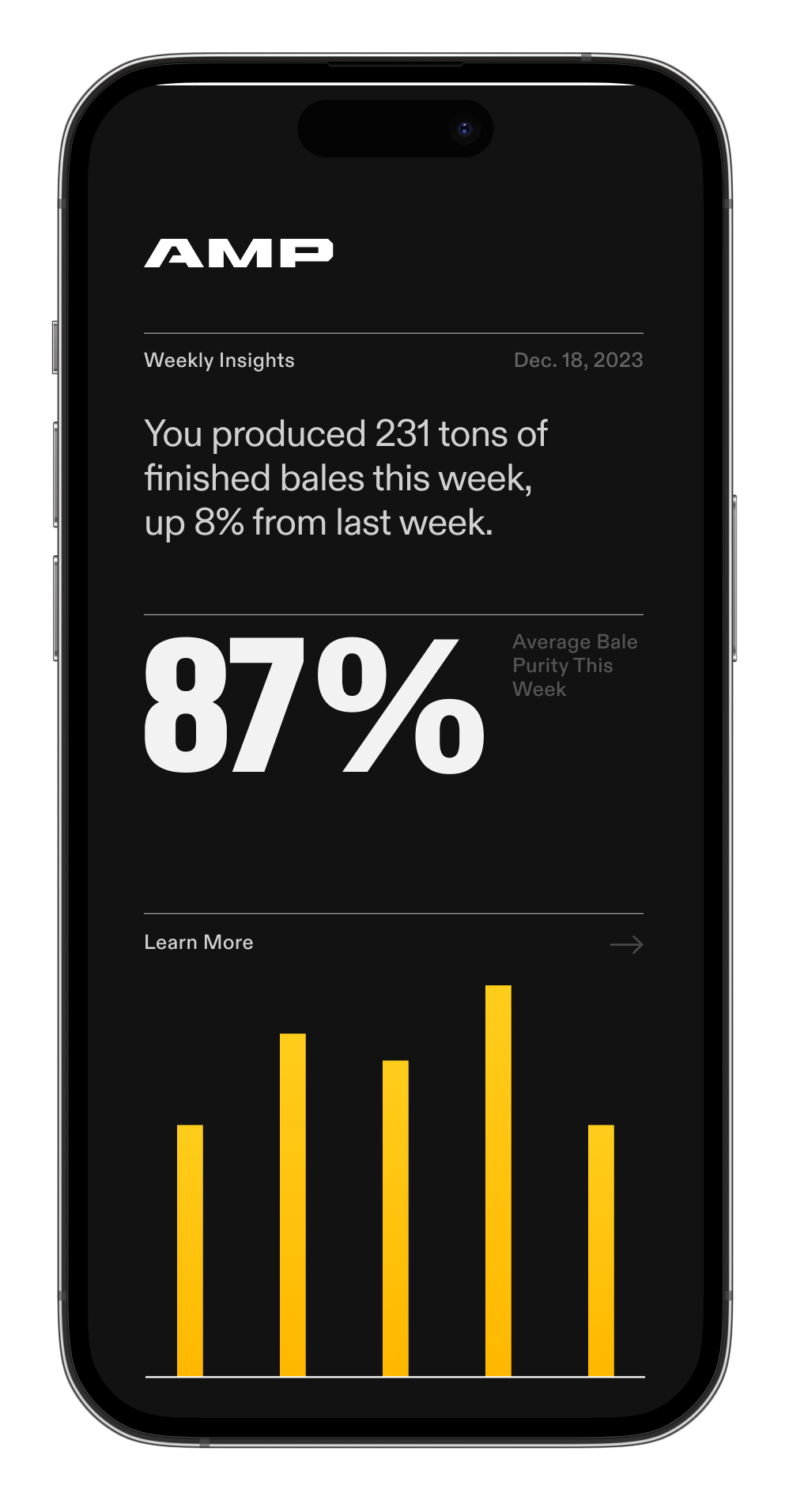

Gain Clarity on What's in Your Wastestream

All AMP technology includes Insight, with real-time performance data. Upgrade to Insight Premium (standard on AMP ONE) for real-time material stream characterization and composition and purity of finished bales.

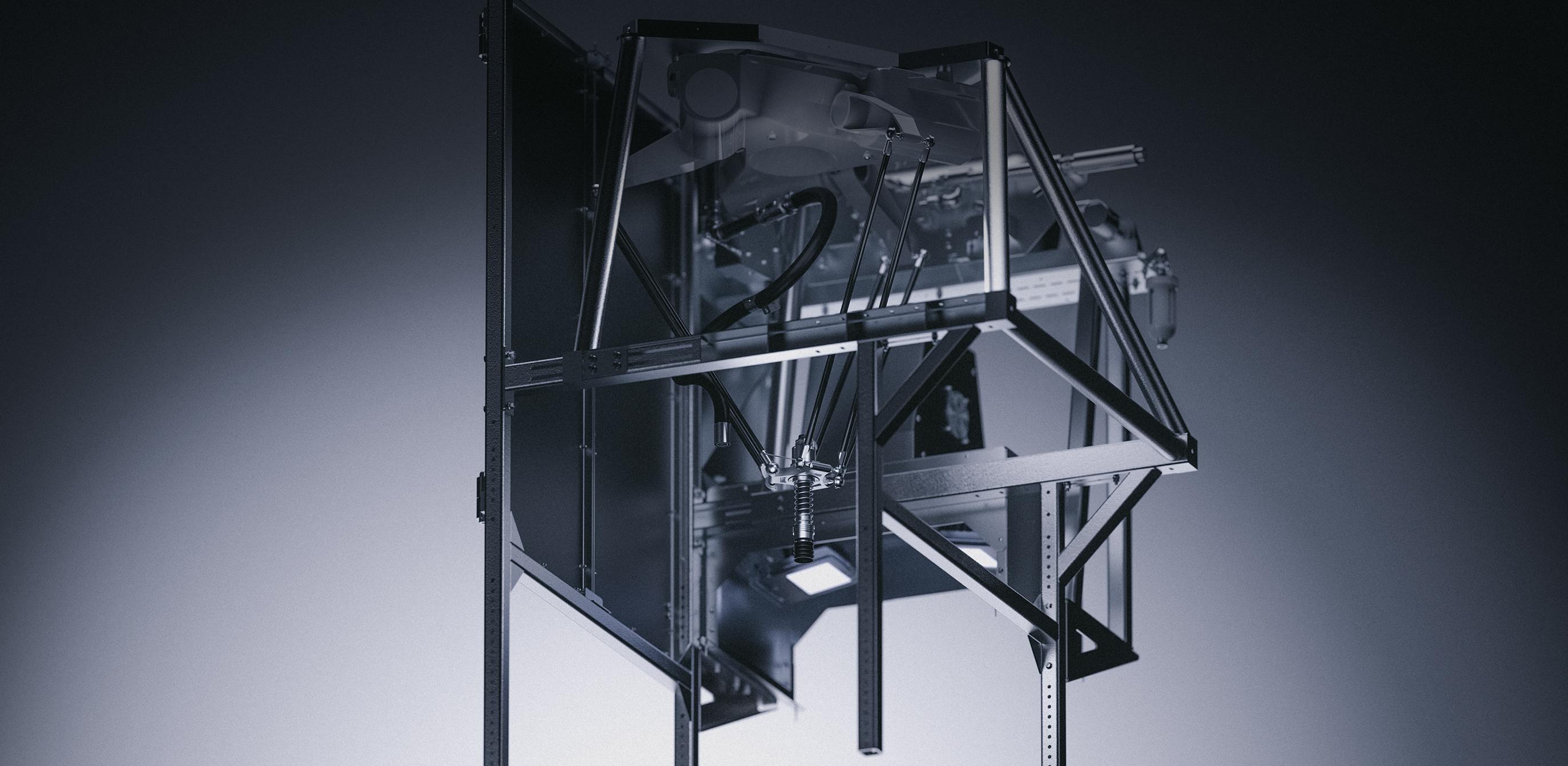

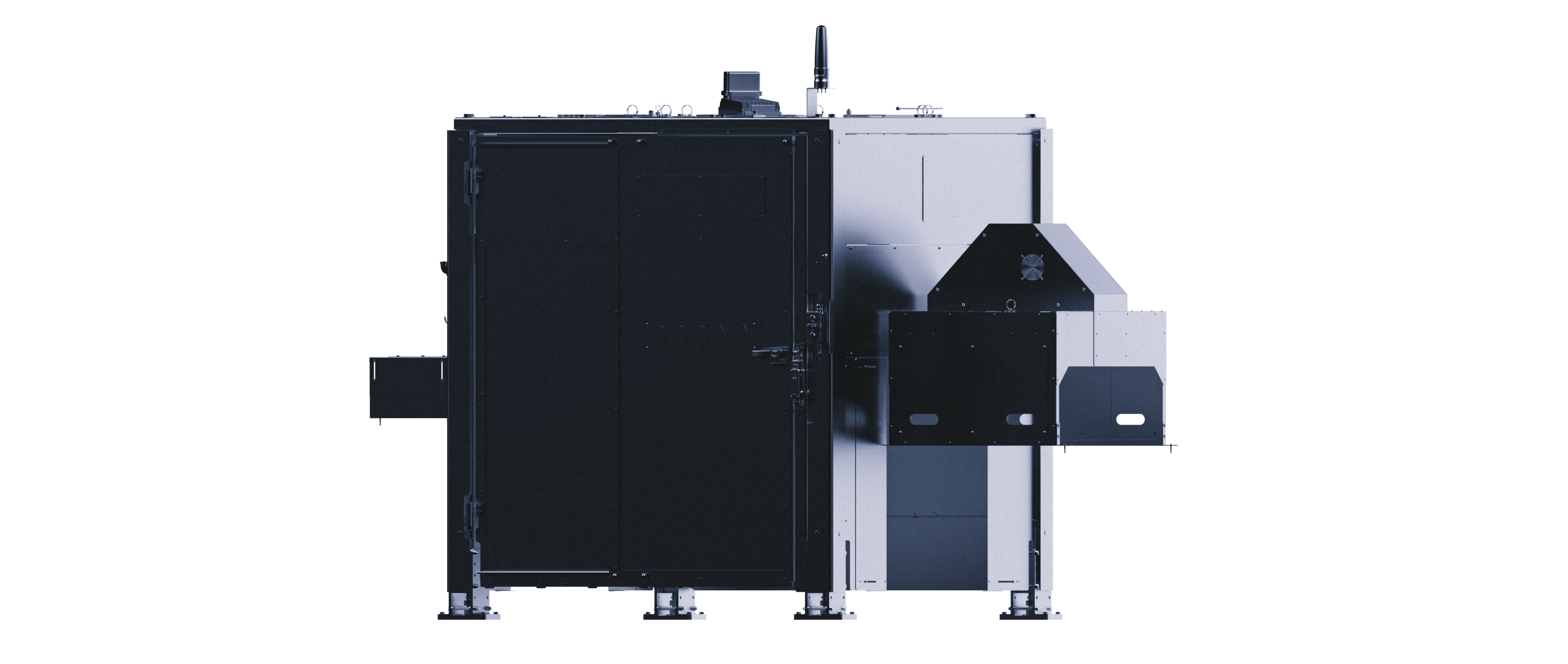

AMP ONE

A SMARTER MRFThe first zero-manual-sortation MRF, AMP ONE facilities deploy Smart Sortation at scales of 15k–100k+ ton/year. Ready to commission in only 9 months.

Put the power of AMP Smart Sortation™ to work for you.